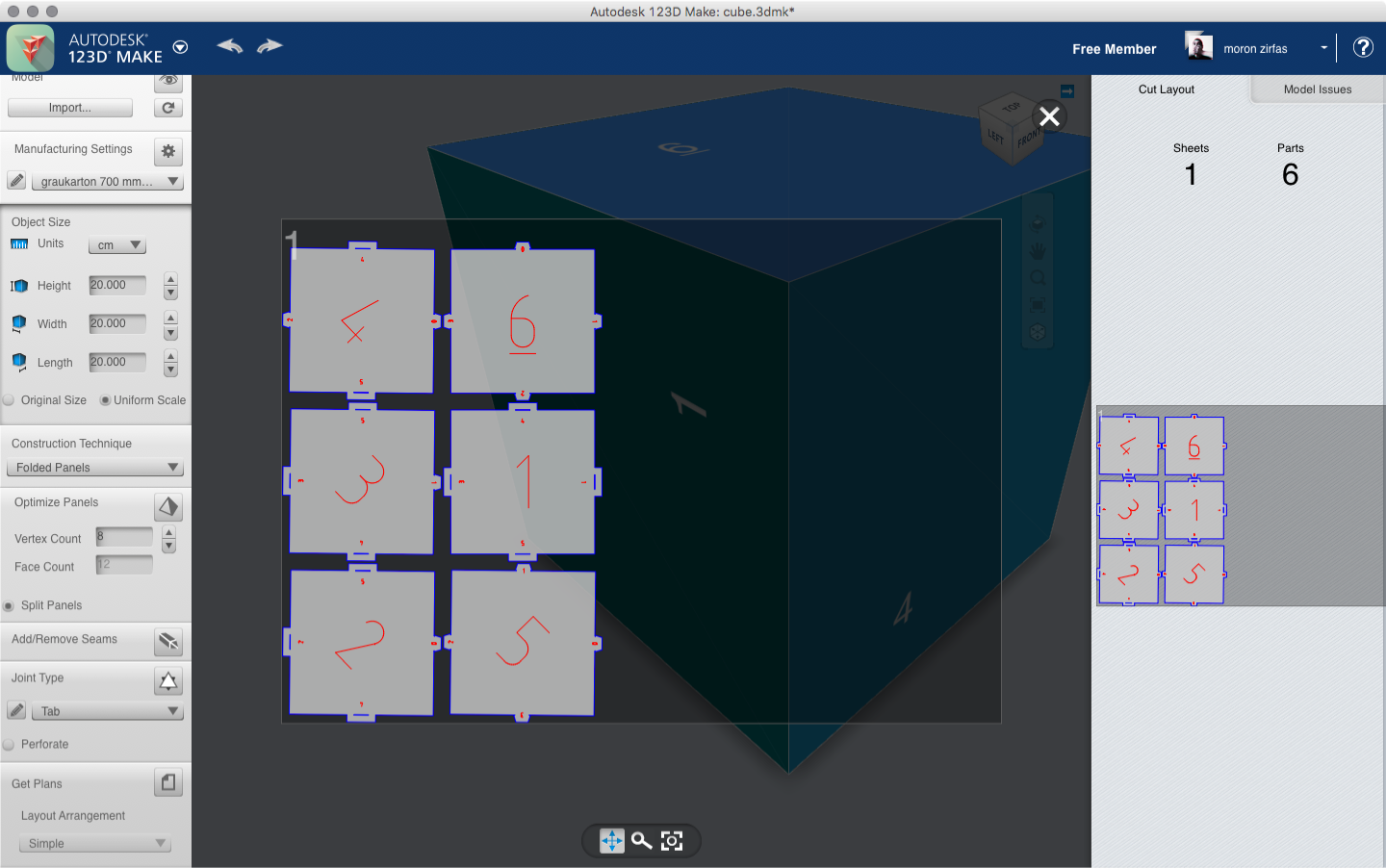

That is not possible with STLs unless you employ glorified hacks to make it work. Note how the 3MF file can carry multiple pieces of meta data for manufacturing of a part.Īccess to print settings and machine information also means you have total control of your support structures and can use a single file to carry that information to your printer. 3MF export from Fusion 360, with both tabs of meta data shown. This game-changer helps you keep all your manufacturing data where it belongs: centralized to all the relevant design data. Fusion 360 includes an additive manufacturing space covering all the settings mentioned above and allows you to export STL and 3MF files. The file format’s ability to carry metadata for your print settings and machine information also enables something exciting: independence from machine-specific slicers. What about manufacturing process information? 3MF has you covered there too.

#DOWNLOAD SLICER FOR FUSION 360 SOFTWARE#

The same principles have kept the MIDI format for transferring data between hardware and software relevant since its first public release in 1983. If you have dabbled in music production, you are likely familiar with how this works. 3MF files are coded to be future-proofed. The companies behind 3MF are also constantly working on improving and updating what 3MF file formats can do. Since 3MFs take advantage of XML formats, information like latticing part internals (for example, data when using the lattice extension in Fusion 360) is also carried over. This minimizes errors and ensures that anyone with the file can repeat your machine settings and part geometry. When using 3MF format with SLS, packing information, how many copies of the part will be made, and all the previous data mentioned previously comes in a single file. The same data imported as an STL, note that the color information is missing, and that the dialogue box requires a unit size to be defined by the user.ģMF also enables instances of parts to be captured, including their locations.

#DOWNLOAD SLICER FOR FUSION 360 CODE#

You can even open the XML to read what the part will do and modify its code directly. Note that there is no units tab in the right dialogue box, because the 3MF file includes that information.ģMF files use a human-readable XML-based format, so they can store tons of data on what needs to be created by the machine without requiring accompanying print settings in a separate file. A 3MF file being imported to Fusion 360’s mesh workspace. STLs do not even have units! Even though they carry this much data, 3MF files are still significantly smaller than STL files. For one, 3MF files carry way more information, including unit information, color and texture information for multijet prints, relative position in space, and so much more. What makes 3MF files revolutionary and special enough to abandon STL files? The improvements that 3MF brings to the table are equivalent to switching from BMPs to PDFs. ⦁ Many people are unaware of alternatives.Įnter 3MF, a file format developed by a consortium of companies working together to advance 3D printing capabilities and technologies. ⦁ 3D printers only support mesh-based files in their slicers. ⦁ STL is still the standard file format for many users. IF STL format is so terrible, why do we use it? There are three answers: As a result, we need to attach STLs with a list of manufacturing specifications when working with a team or a third party to get a part made. That is the essence of why they are so massive, inconvenient, and destructive to your geometry.Īdditionally, STLs do not carry any machine information, settings for printing, or any other helpful information needed to recreate the file.

Therefore, only raw information can be carried over.

Have you ever wondered why your STL can sometimes be as much as 10x the file size of your original file? Well, STLs are a mesh-based architecture, so they cannot store information as a mathematical representation. Some people still experience faceted prints of their parts because STLs interpret your data and essentially create a facsimile of your part, not an accurate representation. With that context in mind, it makes a lot of sense why STL format was created to begin with - translating curves and compound surfaces into machine data would be an astronomical amount of code to run. STL files were designed with additive manufacturing in mind, translating design data, typically NURBS or BREP based, into a mesh for 3D printers to interpret. STL format is ancient in computer terms, as it was first released in 1987 by 3D systems.

0 kommentar(er)

0 kommentar(er)